Mineral Ores

Mineral Ores

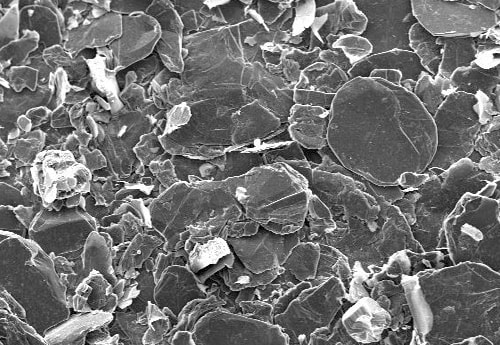

Chrome Ore Sand – Foundry Grade

Trans India Solutions offers Chromite Ore of superior quality to steel, foundry and refractory industries in India and abroad.

Properties of Chrome Ore Sand – Foundry Grade

| Item | Details |

| Cr2O3 | 46% Min. |

| SiO2 | 1% Max. |

| Size | 40-50 AFS |

We offer quantities as requested.

Brown Fused Alumina

Brown Fused Alumina (BFA) is made from Calcined Bauxite, and is physically hard and tough. Refractory grade BFA is used as a raw material in the manufacture of high alumina refractory items.

Trans India Solutions has supplied a lot of BFA to refractory industries in India. The material is mostly sourced from China.

Chemical Composition

| Item | % Composition |

| Al2O3 % | Min. 95.0 % up |

| Fe2O3 % Max. | 0.5 % |

| SiO2 % Max. | 1.0 % |

| CaO % Max. | 1.0% |

We offer quantities as requested.

Sizes:

-3+6 BSS Mesh

-6+16 BSS Mesh

-16+72 BSS Mesh

-240 BSS Mesh (or) as per requirement in different sizes.

Natural Flake Graphite

Flake Graphite is one of the most famous forms of Natural Graphite. It is used in many industries, especially Refractory Industries, Chemical and Fertilizer Industries. In Refractories, they are used in manufacturing of Alumina-Graphite shapes, carbon-magnesite bricks, monolithics and crucibles.

We supply Natural Flake Graphite with below specifications:

- Fixed Carbon – 70% Min. and above, 90% Min. and above

- Mesh Sizes Available – (BSS) as per requirement

Fused Magnesia

We supply refractory grade Fused Magnesia. It enhances the performance and durability of basic refractories as a result of its higher bulk specific gravity and large crystal size. They have excellent corrosion resistance, making it suitable for using in steel industry and other furnaces etc.

We supply fused Magnesia with below specifications:

- MgO – 96% Min. (and up)

- SiO2 (Silica) – 1%. Max.

- Lime:Silica Ratio – 2:1

- Density – 3.4 gm/cm3 Min.

- Size – As per user requirement (usually 1 to 50 mm)

Silicon Carbide

Silicon Carbide, also known as Carborundum, is a compound of Silicon and Carbon with chemical formula SiC. It is synthesized in a resistance-type electric furnace at temperature exceeding 2500 Degree Celsius, through the reaction of Silicon with Carbon.

Their qualities include:

- Chemical Inertness at high temperatures

- High resistance to abrasion

- High resistance to thermal shock

They are used in several refractory applications like kiln furniture, bricks for blast furnaces and zinc furnaces, crucibles, monolithics, runners in melting furnaces etc.

We supply Silicon Carbide with following specifications:

- SiC – 95% Min. (and above)

- Al2O3 – 0.8% Max.

- SiO2 + Si – 1.2% Max.

- Sizes Available – in Mesh (BSS) as per requirement